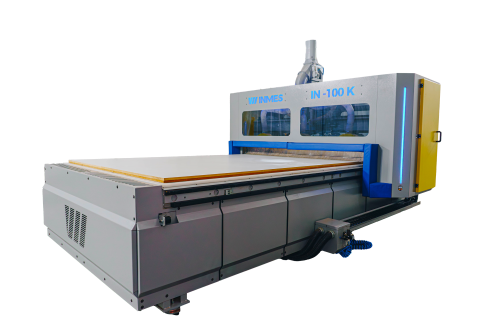

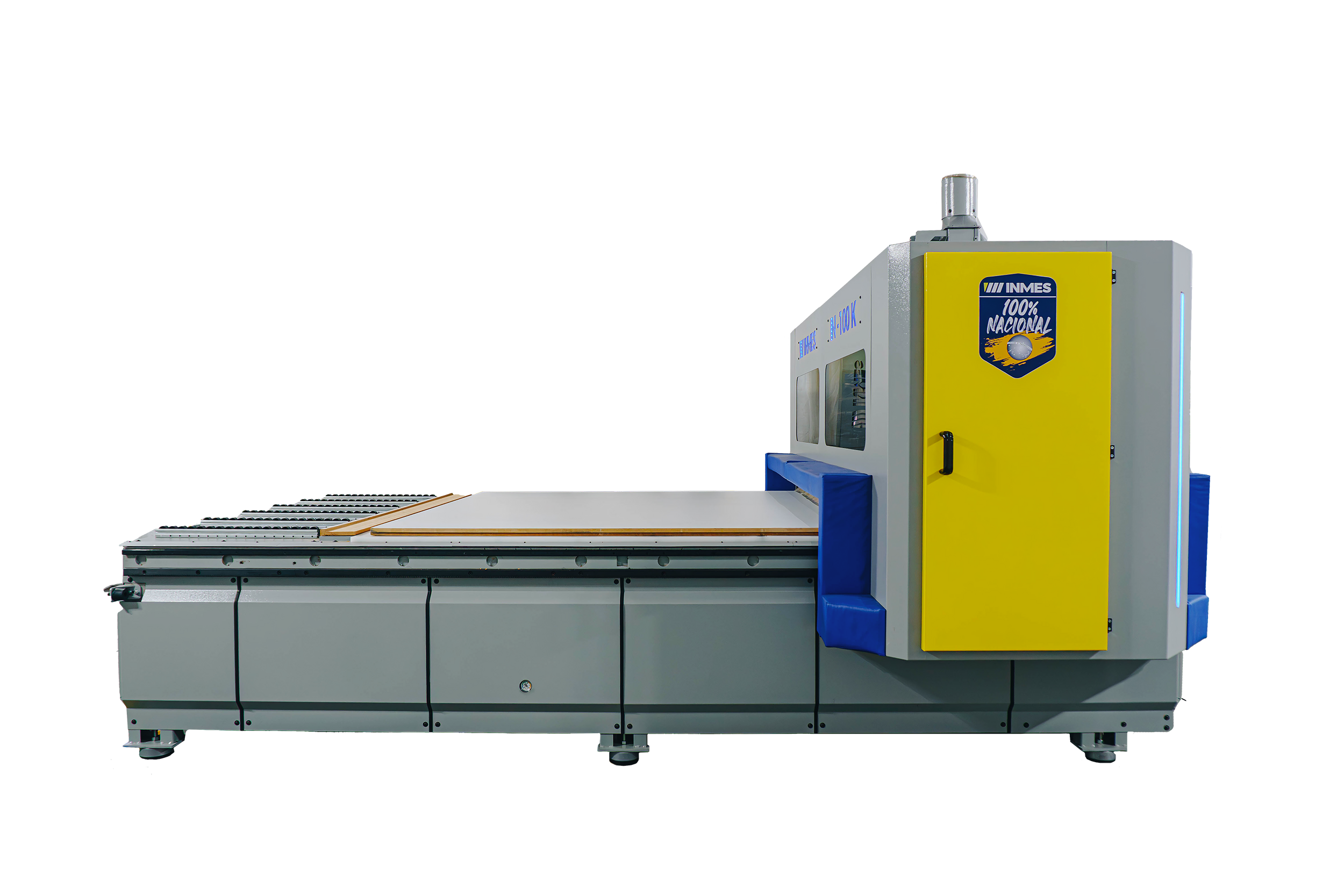

NESTING IN-100K

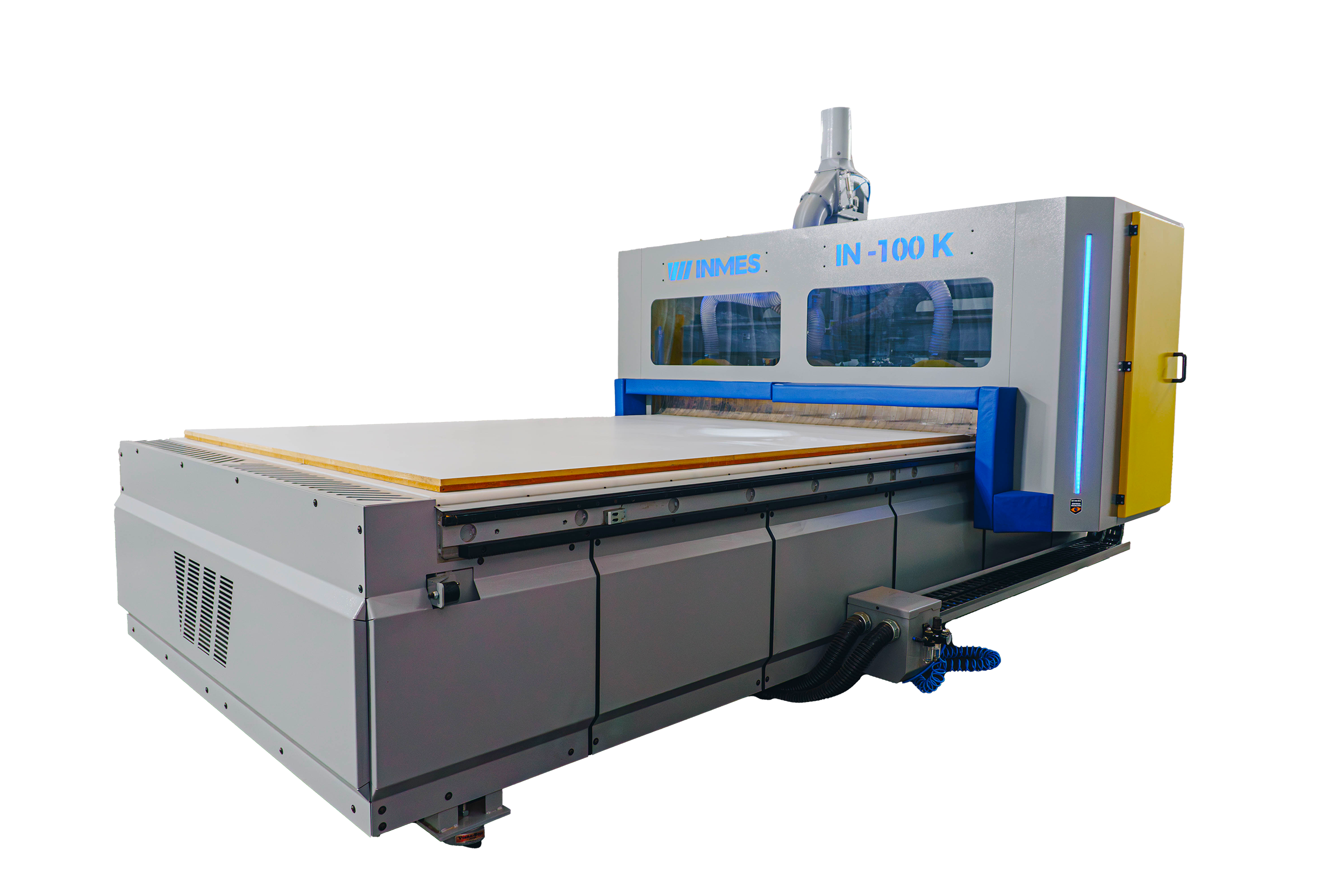

The Nesting IN-100K CNC Machining Center represents the next step in the evolution of machining and drilling flat sheets of MDF, MDP, plywood and similar materials. Developed with cutting-edge technology, this machine offers a perfect combination of precision, automation and efficiency.

NESTING IN-100K: QUALITY AND INNOVATION FOR YOUR JOINWORK

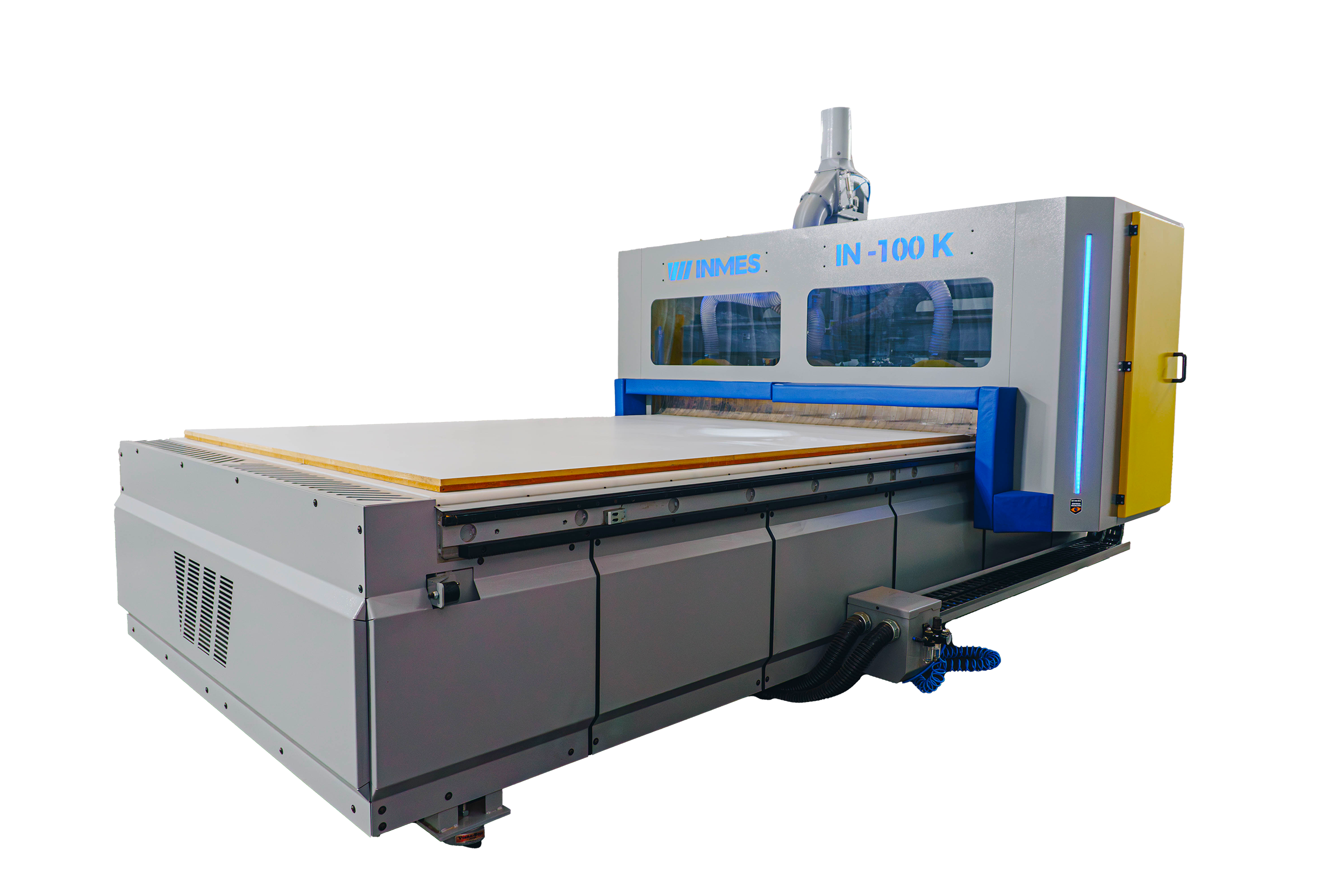

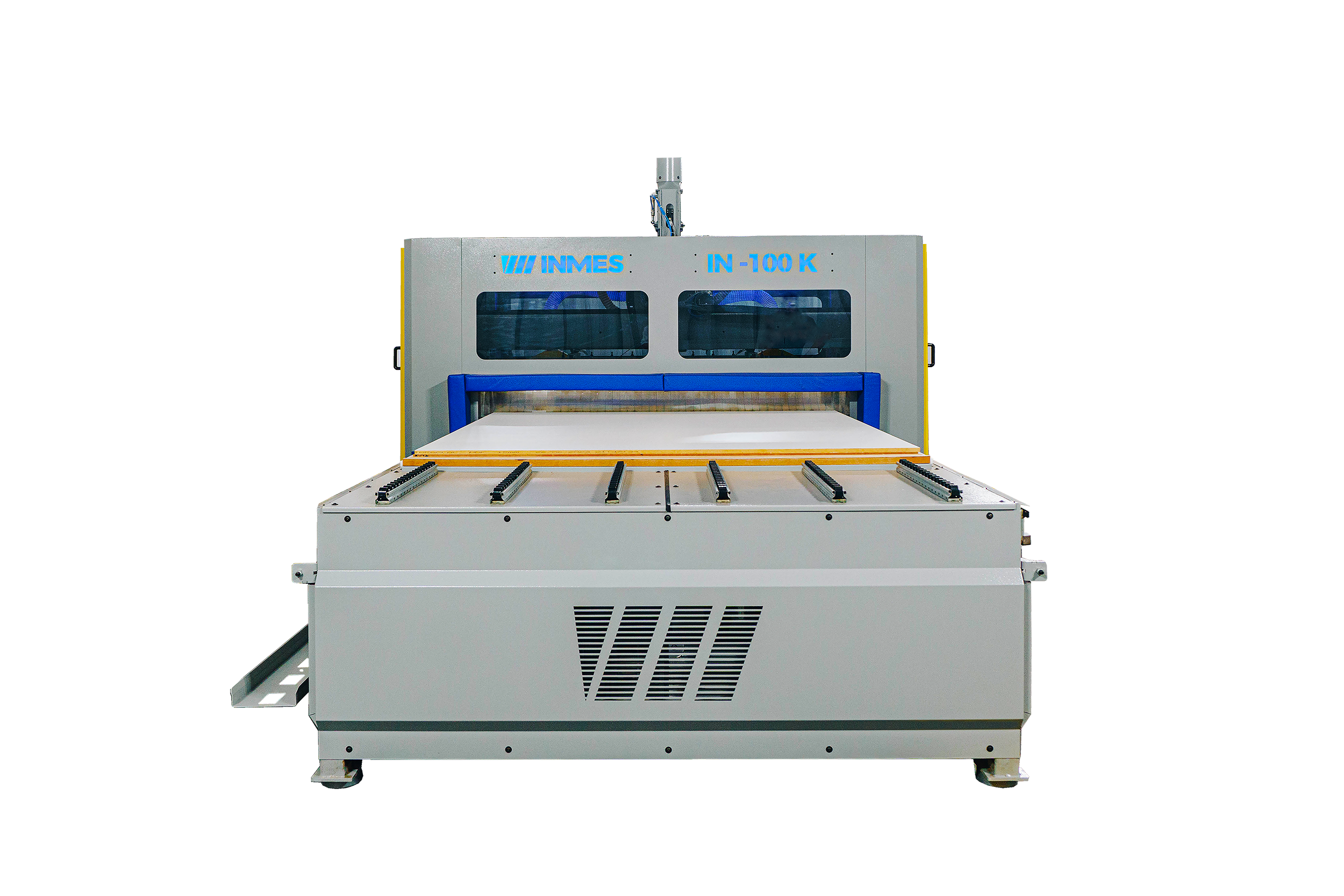

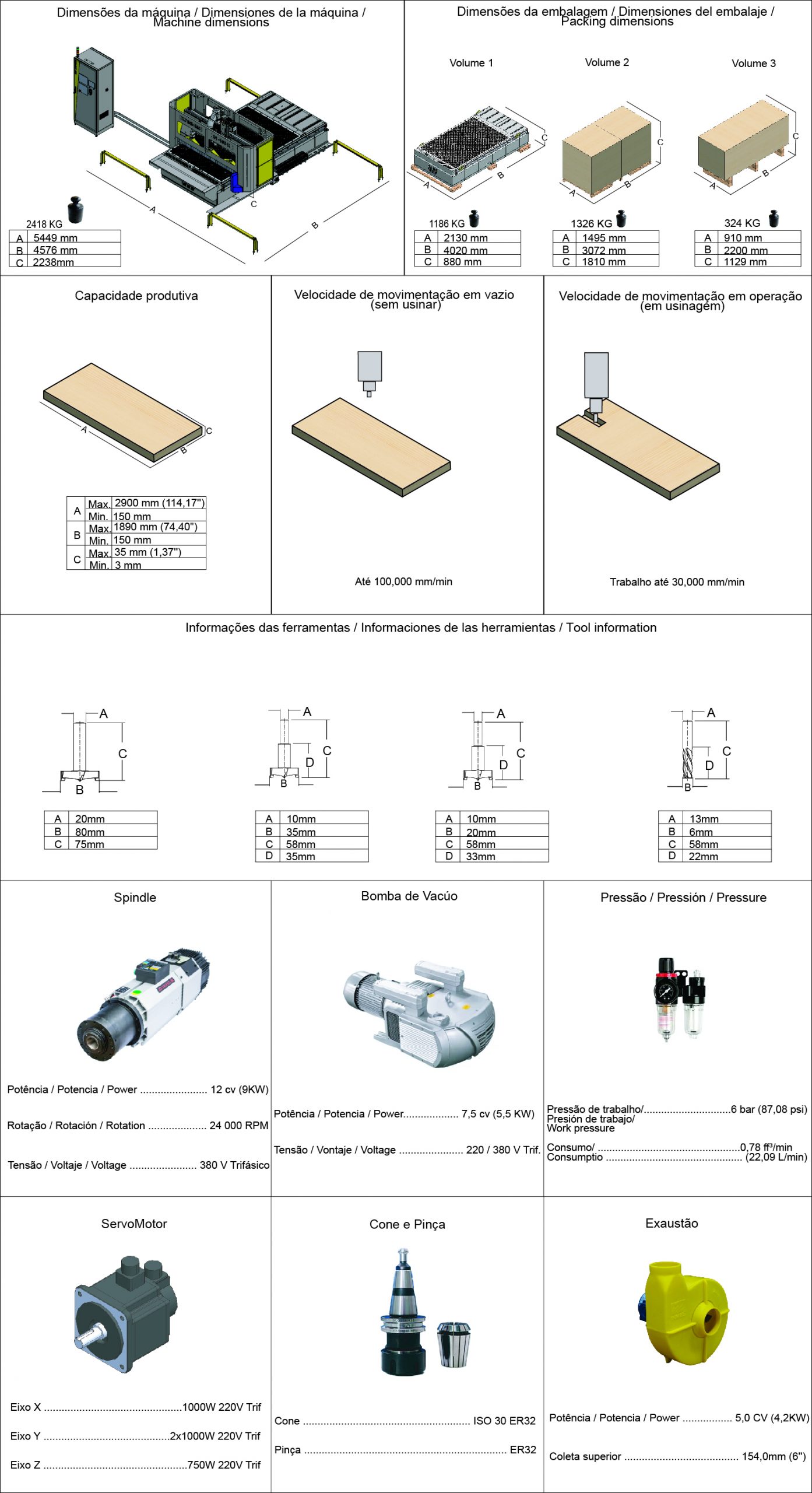

The “NESTING IN-100K” is a CNC machine for cutting flat sheets through the nesting process, using milling and fixing the material with a vacuum pump. Its robust mechanics feature a reinforced structure developed in high-strength metal profiles, welded by robots. With a useful working area of 1890x2900x200mm (X/Y/Z), the machine offers a remarkable capacity for cutting and machining sheets up to 32 mm, using the appropriate tool.

GREATER PRODUCTIVITY AND EFFICIENCY

The maximum working speed reaches up to 30,000 mm/min, varying depending on the type and thickness of the material, while the empty travel speed reaches an impressive 100,000 mm/min. The cutting head has a 9 Kw (12 HP) Spindle with a maximum rotation of 24,000 RPM, offering flexibility of adjustment via software or control panel. The machine uses standard ER32 collets, accepting tools with shank diameters from 2 mm to 22 mm.

GREATER ROBUSTNESS

The drive motors include 1 kW three-phase AC servo motors on the Security is guaranteed by an enclosed gantry with monitored access and a work area monitoring system with an active optoelectronic protection device.

COMMITMENT TO SAFETY

The machine features an advanced electrical protection system, with fault detection relay and phase inversion to protect the vacuum pump and the electrical system. The lack of compressed air in the network is monitored by a pressure switch sensor that integrates a protection system. Lubrication is automatic on all guides, using a timed pump with precise flow control.

TECHNOLOGY AND INTEGRATION

The dedicated CNC control eliminates the need for a computer on the machine, using ISO Code files and integrating with the main CAD/CAM software on the market. iNest, ISO language optimizer and generator software for PC/Windows®, comes with the machine free of charge, offering exclusive functionalities, such as creating, editing and importing parts lists, 3D visualization and optimization considering the real contour of the parts.

PRACTICALITY

Its practical interface allows the generation of labels for printing, facilitating manual identification of parts. Furthermore, the machine saves scraps for future use, creates reports on sheets to be used and allows blocking of the direction of the shaft and rotation of parts. Its training and technical delivery, together with integration with the main software on the national market, make the “NESTING IN-100K” a complete choice for optimizing the production process in woodworks and industries.

TOOLHOLDER

Automatic change system integrated into the gantry that supports up to 12 tools.

SQUARE STOP

6 pneumatic square stops for aligning the sheet or part.

VACUUM TABLE

Table divided into 16 vacuum areas composed of individual electronic valves, enabled according to the movement of the Spindle or manually activated.

PUMP VACUUM

Power of 5.5Kw (7.5CV), air-cooled.

TOOL KIT

Basic kit for training and releasing the machine during technical delivery.

DISCHARGE SYSTEM

Unloading system with self-adjusting pusher, which adjusts to the height of the sacrificial table without the need for adjustment with each pass or change.

EXHAUST TECHNOLOGY

Advanced engineering system with low pressure loss that increases exhaust efficiency.

TECHNICAL SPECIFICATIONS:

English

English Português

Português Español

Español