Drill Point to Point IF-8500

The Point-to-Point Drill IF-8500 allows you to automate the drilling process, making drilling and assembling furniture much more agile.

IF-8500 POINT-TO-POINT DRILL, FLEXIBILITY, PRODUCTIVITY AND CONNECTIVITY, WITH MUCH MORE QUALITY:

A GREAT HIT AT YOUR FURNITURE WORKSHOP

A modern furniture factory, needs Flexibility and Quality in production, so Inmes has developed a modern and affordable machine for those who do not give up an advantageous cost-benefit. In addition to its design, the IF-8500 comes equipped with a modern CNC system that allows the manufacture of various parts in a very short time.

MORE PRODUCTIVITY.

A modern CNC system, provides greater productivity in the process of drilling, milling and grooving panels, in the manufacture of furniture.

MORE FLEXIBILITY.

A great new feature of the IF-8500 is the GCAD software that comes with the machine. With it, it is possible to easily design the parts to be machined directly from a computer in your office.

MORE CONNECTIVITY;

The transfer of programs to the machine is instantaneous, via wifi, network cable or USB, the operator sends the programs generated in the GCAD software or the project software², without having to stop the process.

PAINEL TOUCH SCREEN

With a 7 ”touch screen panel it is easy to view work operations.

BARCODE READER

For greater agility, it is possible to use a barcode reader, which comes with the machine to call the program corresponding to the part in execution.

PLATE POSITION

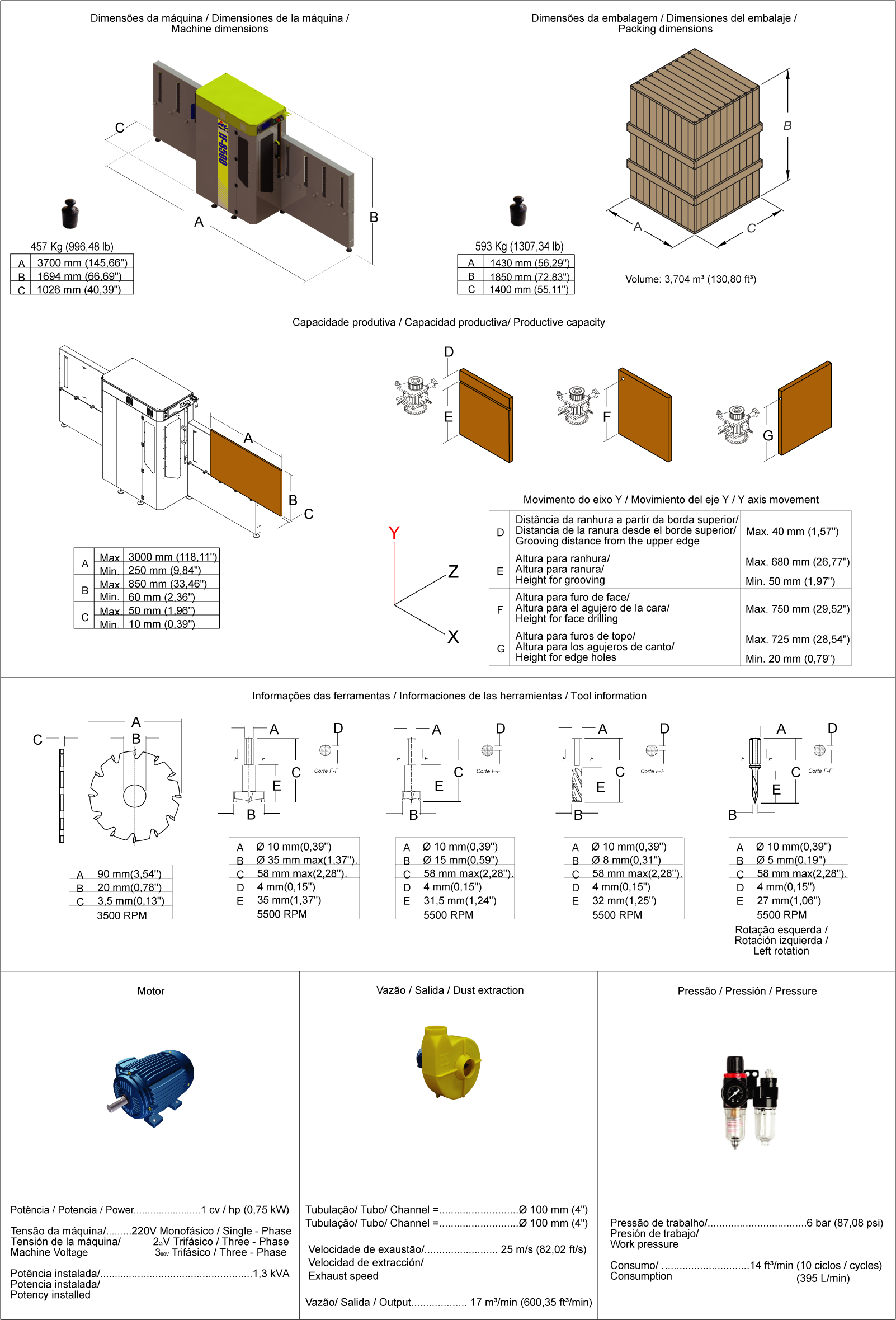

On the IF-8500 Drill, it is possible to machine parts 850 mm high by 3000 mm long.

LUBRICATION SYSTEM

The lubrication system of the IF-8500 Drill is automatic, with easy access.

SENSOR CORRECTION

For greater precision in drilling at the edges, the IF-8500 has a measurement sensor that corrects any errors in the cut.

HEAD MULTIFERRAMENTAS

With a head for five tools that come with the equipment, it is possible to carry out the most diverse operations for the construction of quality furniture.

CONNECTIVITY

The IF-8500 Drill can be connected to the network via Cable, USB or Wifi port, ensuring total connectivity.

SEE MORE SOME FEATURES OF THE IF-8500:

* Comes with the machine:

- Broca of 35 mm,

- Broca of 15 mm,

- Broca of 5 mm,

- 8 mm bur,

- Saw blade Ø 90 mm x 3.4 z24,

– Chave allem 2,5 mm,

- Key for changing the saw blade.

* Barcode reading system;

* Support for barcode reader pistol;

* Lan and pendrive connections;

* Automatic lubrication system;

* Painel touch screen de 7″;

* Option to exit the pieces from the right or left;

* Exclusive software for parts design;

* Comes with air nozzle for cleaning parts.

TECHNICAL SPECIFICATIONS:

** The photos on this website are illustrative.

English

English Português

Português Español

Español