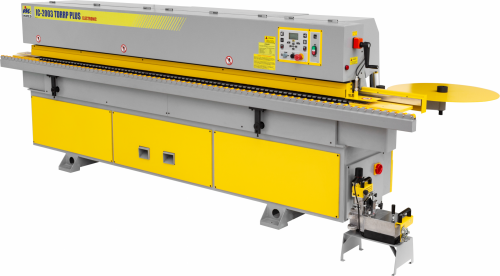

IC-1000 DRP Edge Banding Machine

INMES presents the IC-1000 DRP Edge Gluer, a revolutionary solution developed to meet the growing demands of the furniture sector. Designed with a flexible design and cutting-edge technology, this machine raises the bar for productivity and quality in edge work.

INMES met market demand with the IC-1000 DRP EDGE GLUER, a true innovation destined to transform modern carpentry. With a flexible design, this machine allows quick change of gluers, easily adapting to different MDF standards. Its advanced control panel, equipped with a touch screen interface, incorporates an intelligent temperature control system, reducing costs when entering standby mode. In addition to expanding possibilities, with the lath gluing feature, the IC-1000 DRP offers excellent value for money, thanks to its multifunctionality and the extended useful life of the components. It's the smart choice for woodworkers who value quality and efficiency.

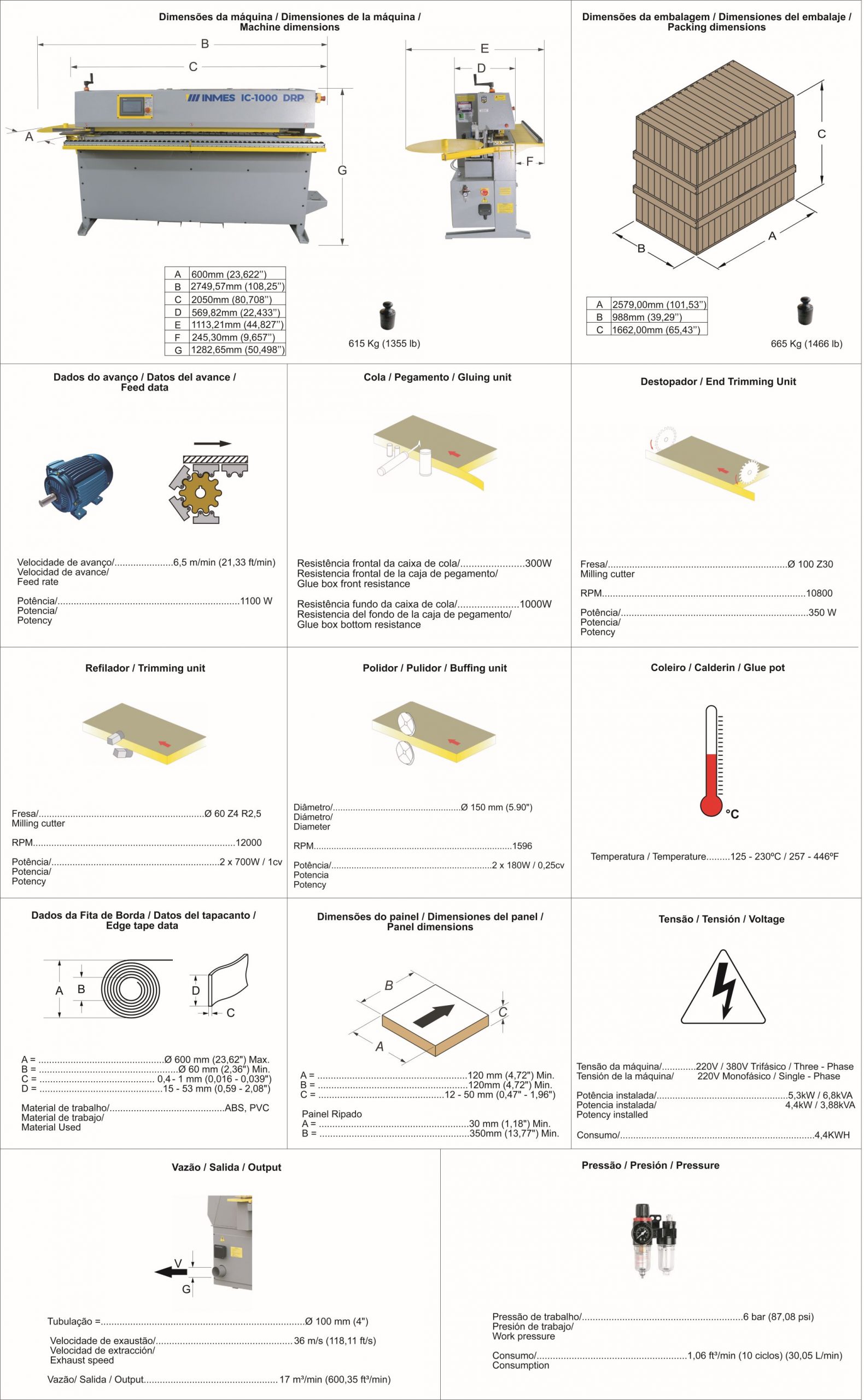

Gluing slats

Allows the creation of slats with a minimum width of 30mm, expanding the possibilities in carpentry. Its flexibility and adaptation to MDF standards guarantee a precise, high-quality finish, making it the ideal choice for those looking for innovation, practicality and durability in projects with greater thicknesses.

Destopador

Equipped with an efficient stopper system, allowing the precise removal of excess tape. With this integrated functionality, carpenters can ensure a clean and uniform end result, without the need for additional tools. This makes the IC-1000 DRP even more versatile, providing practicality and agility in the manufacturing process, while ensuring quality and precision at all stages of work.

Refiller

It has an integrated trimmer, which guarantees an impeccable finish on the edges of the pieces. The trimmer is responsible for trimming excess material, such as excess edge tape, providing a precise and uniform cut. This feature is essential for achieving smooth, imperfection-free edges, optimizing production time and reducing the need for rework. The presence of the trimmer on the IC-1000 DRP makes the gluing process even more efficient and of high quality, guaranteeing professional results on each piece.

Polisher

Equipped with an integrated polisher, which provides a high quality final finish on the glued edges. After gluing and refiling, the polish ensures a smooth and uniform shine, eliminating imperfections and leaving the edge of the piece with a professional appearance. This feature is essential for improving the aesthetics of the product, giving it a perfect finish without the need for additional manual polishing steps. With the polisher, the IC-1000 DRP offers a more agile, efficient production process with high precision and quality results.

Change of collar

It offers the convenience of quickly changing the collar, which makes the production process more agile and efficient. With an intelligent design, changing the collar can be carried out simply and quickly, without the need for complex tools. This functionality allows carpenters to easily adapt the machine to different types of materials and MDF patterns, optimizing time and ensuring greater flexibility in the production line. This makes the IC-1000 DRP a highly productive solution for those looking for agility and versatility in their projects.

English

English Português

Português Español

Español